DYNTEK presents StiFlex,

a modular system of steel stiffeners, connectors and wall

ties for both internal and external brick/block walls.

Manufactured from steel, StiFlex is the

ideal replacement for traditional cast-in-situ reinforced

concrete stiffeners. StiFlex is easier to install, providing

savings in time and manpower.

Anatomy of the StiFlex™ Stiffener

Benefits

StiFlex combines the work of steelbenders, carpenters, bricklayers

and concreters into a single product.

W ith StiFlex, only bricklayers are required to complete the

entire wall.

StiFlex stiffeners can be lifted and installed by two persons,

without the use of lifting equipment.

StiFlex provides options of corrosion protection and is fire

tested by the Singapore Productivity and Standards Board (PSB)

for 2 hour and up to 4 hour fire rating. Details available

upon request.

StiFlex uses a simple sliding process to fasten wall ties;

connectors sleeve into vertical or horizontal members with

tolerance gap designed to allow flexibility in StiFlex length

variation. No bolts, nuts or welding is required.

StiFlex Stiffeners has been tested for sound transmission

loss and results compared favourably against concrete stiffeners.

Copy of test report available upon request.

Construction with wet masonry can begin immediately after

installation of StiFlex stiffeners, thus saving time.

StiFlex Stiffeners has been tested for moisture build up and

heat transfer. The results compare favourably against concrete

stiffeners. Copy of test’ reports available upon request.

StiFlex Standard Profile Sizes

Product Code |

Wall Width (mm) |

Description |

SC100/90

SC125/100

SC125/150A

SC200/150 |

100

100 / 150

100 / 150

200 |

StiFlex

stiffener used either vertically and/or horizontally |

SCR100/90

SCR125/100

SCR125/150

SCR200/150 |

100

100 / 150

100 / 150

200 |

StiFlex

end connector used between vertical/horizontal StiFlex

to reinforced concrete end. |

SCS100/90

SCS125/100

SCS125/150

SCS200/150 |

100

100 / 150

100 / 150

200 |

StiFlex

joint connector used for connecting horizontal to vertical

StiFlex member. |

SAG12T |

100

/ 200 |

StiFlex

L-tie 120mm length used to connect at any position between

vertical StiFlex and brick/blockwork. |

SAG20TA |

100

/ 200 |

StiFlex

L-tie 200mm length used to connect at any position between

vertical StiFlex and brick/blockwork. |

SAG12R |

100

/ 200 |

StiFlex

L-tie 120mm length used to connect between reinforced

concrete end and brick/blockwork. |

SAG20RTA |

100

/ 200 |

StiFlex

L-tie 200mm length used to connect between reinforced

concrete end and brick/blockwork. |

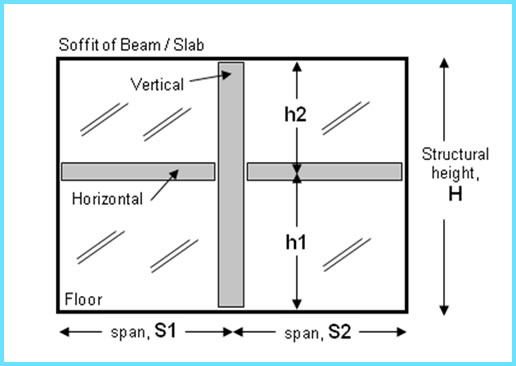

For StiFlex proposal, please provide the

following:

a) Wall thickness

b) Height of wall (structural height), H

c) Spacing of vertical stiffener, S1 & S2

d) Horizontal stiffener level, h1 & h2

e) External or Internal Wall

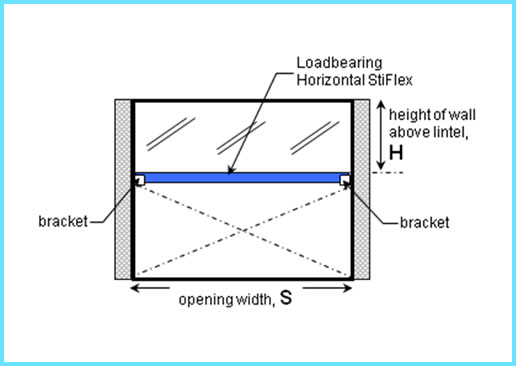

a) Wall thickness

b) Type of wall (e.g. clay brickwall, lightweight blockwall,

etc.)

c) Height of wall above lintel, H

d) Width of opening, S

e) Bracket/s connection to concrete column or vertical StiFlex

f) External or Internal Wall

About StiFlex Stiffener Installation

1. The length of each vertical stiffener could ideally

be up to 250mm less than the opening height.

2. The length of each horizontal stiffener should be:

- up to 250mm less than the clear distance (span) between

vertical stiffener/s and/or column/s – for Non-loadbearing

situation and;

- up to 20mm less than the opening width between vertical

stiffener/s and/or column/s – for Loadbearing situation.

3. When necessary, Stiffener lengths can be shortened on

site using an angle grinder

4. End Connector SCR, should be fixed using 2 fasteners

(3.8mm diameter, 25mm penetration, Powder Actuated) on each

side of the plate with each nail at least 75mm apart. Each

fastener should also be at least 75mm from the closest concrete

edge. There should be 4 fasteners for each connector.

Installation Procedure

|

|

| Insert the End

Connector brackets into both ends of the stiffener and

position the stiffener in an upright position over its

intended location. |

Locate the stiffener

precisely over its final position and affix to the floor

or beam using 2 fasteners (3.8mm diameter, 25mm penetration)

on each side of the end connector (base). Check for verticality

and fasten the top connector in the same way and this

time slide out the end connector till it makes contact

with soffit. Proceed with blockwork. |

|

|

| Insert L-tiles

by sliding them into the gliding slots and embed firmly

onto the mortar. L-ties should be used on every 3rd or

4th block course as required (interval of 400mm centres

recommended). |

At the last

blockcourse before the horizontal stiffener, leave out

the two end pieces of block. Provide bedding mortar on

the blockcourse. Install Joint Connector brackets into

both ends of the horizontal stiffener. |

|

|

| Attach horizontal

stiffener to the vertical stiffener by sliding the Joint

Connector into the appropriate slot. The connector bracket

is designed to allow free-play in order to ease installation. |

Fill in the

end blocks. Proceed with blockwork and plaster when appropriate.

Optional Dyntek MetalLath can be used to assist in plastering

work. |

Examples of StiFlex Stiffeners Used in

Other Situations

Dyntek Pte Ltd 2008-2011

© All Rights Reserved. |